HYDRILYTE® TECHNOLOGY

HYDRILYTE® TECHNOLOGY

Introducing Hydrilyte® – the Future of Hydrogen Storage

The Hydrilyte advantage is built on a core innovation: suspending a solid-state metal hydride powder in a mineral oil. This transforms a high density metal hydride, constrained by sluggish kinetics and complex handling into a material that is effectively inert, is pumpable and has outstanding reaction kinetics, while still maintaining a high volumetric density.

Unlike other methods, the Hydrilyte® hydrogenation/dehydrogenation process doesn’t degrade the carrier liquid, ensuring the release of exceptionally pure hydrogen and marking a significant leap forward in efficiency and cost-effectiveness. This approach enables a remarkably simple, reversible cycle that securely stores hydrogen in a dense, stable, solid form while maintaining the safe handling benefits of a pumpable liquid.

HOW IT WORKS

HOW IT WORKS

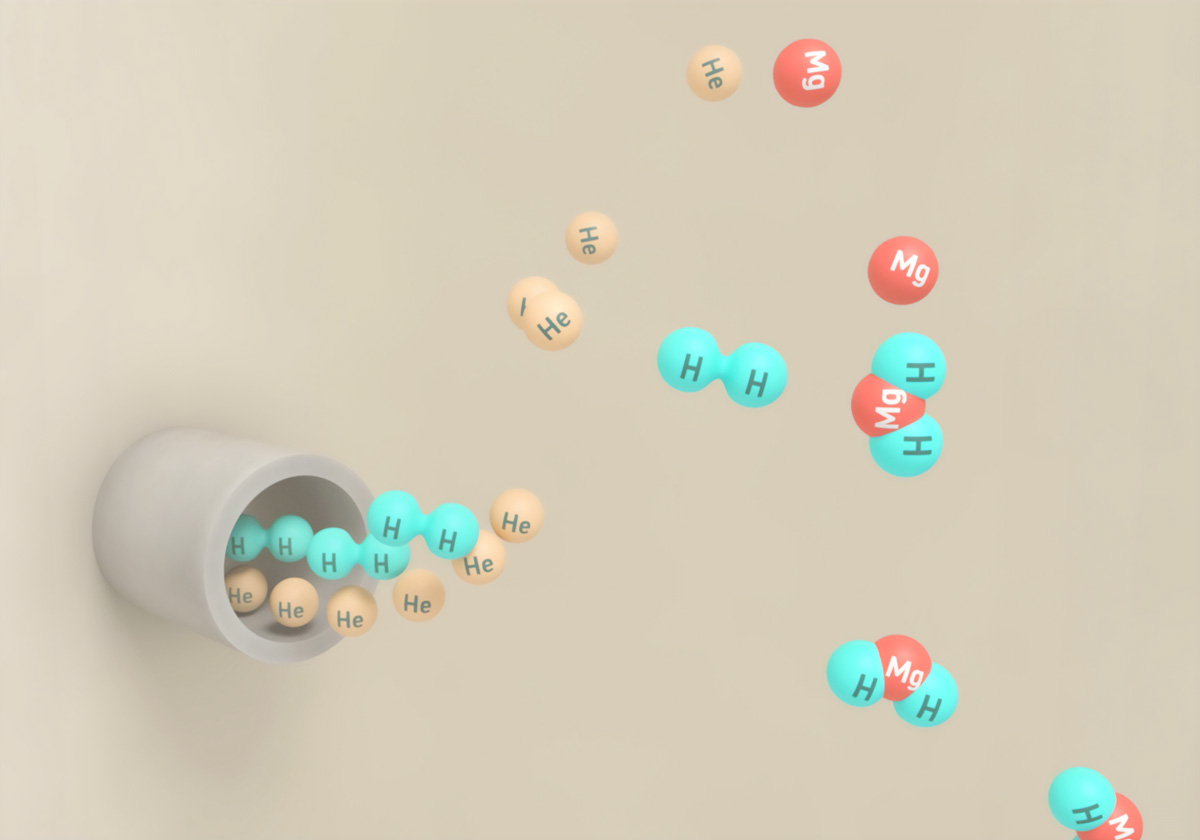

A simple, reversible cycle for safely storing and releasing hydrogen

Innovative technology that makes hydrogen storage, transport, and utilisation safer, more cost-effective, and more practical for a wide range of industries.

Composition and Safety

Hydrilyte begins as a suspension of fine magnesium powder within a light mineral oil. The oil acts as a protective barrier, insulating the otherwise reactive magnesium from oxygen and water, which makes the entire liquid suspension safe to handle and transport under ambient conditions.

Hydrogen Storage

To store hydrogen, the gas is bubbled through the Hydrilyte suspension, triggering an exothermic (heat releasing) reaction as the hydrogen reacts with and bonds to the magnesium, to form a stable solid, magnesium hydride (MgH₂). The hydrogen is now chemically locked in a solid state within the liquid carrier and can be stored indefinitely without loss.

Hydrogen Release

To release the hydrogen, the process is reversed by adding additional heat to the Hydrilyte. This endothermic process breaks down the magnesium hydride, releasing high-purity hydrogen gas and leaving the original magnesium powder suspended in the oil, ready for the next cycle.

Crucially, the mineral oil carrier is not involved in the chemical reaction and is not “cracked” or broken down during hydrogen release. This is a major advantage over Liquid Organic Hydrogen Carriers (LOHC), as it means the hydrogen is released at very high purity without needing costly downstream purification, and the carrier liquid itself does not degrade, minimising make-up requirements during operations.

WHY HYDRILYTE®

WHY HYDRILYTE®

We know our technology is unique within the market, here’re just a few reasons we know it’s a game changer

![]()

Lower Costs

The simple, catalyst free design of the Hydrilyte® plant reduces capital costs. Compatibility with existing fuel equipment for storage and transport also reduces capital and operating costs. The reversible Hydrilyte® hydrogen storage and release process operates without cracking and is highly durable. This ensures that unlike LOHCs a Hydrilyte® plant will have minimal make-up requirements over its lifetime, comparatively reducing operating costs.

![]()

Globally Scalable by Design

Based on magnesium, an abundant element in the earth’s crust and sea water, Hydrilyte® is ready for worldwide production, minimising geopolitical risk.

![]()

Energy Efficient

Less energy required to store and release hydrogen compared to ammonia and LOHCs like MCH and DBT which means higher round-trip efficiency and lower cost of operations.

![]()

Inherently Safe

Our technology is fundamentally non-flammable and non-toxic, avoiding the hazards of compressed hydrogen, liquid hydrogen or ammonia (when used as a hydrogen carrier). Unlike LOHCs Hydrilyte® is non-toxic in a marine spill. Inherent safety enables co-location of large volumes of hydrogen close to sensitive facilities such as data centres or hazardous facilities such as steel plants.

![]()

Extreme Durability

Unlike LOHCs, Hydrilyte® can be reused thousands of times with minimal degradation, ensuring a long and reliable service life.

![]()

No catalysts required

By combining a simpler, more robust design with greater tolerance for variable input, the system delivers a lower-cost and highly flexible hydrogen storage.

![]()

Massively Scalable Storage

A large crude oil tank, of the type found at an oil terminal, could store 2000 tonnes of hydrogen, equivalent to 40GWh of energy from standard fuel cells. Enough to power a 1GW data centre for 40 hours.

![]()

Simple to Transport

As a safe, pumpable liquid, Hydrilyte moves through existing supply chains, staffed by semi-skilled labour, as easily as diesel. Unlike liquid hydrogen or ammonia, its safety characteristics minimise permitting and licensing issues for developers.

![]()

Purification Capabilities

Our process enables the separation of hydrogen from mixed gas streams and storage of the hydrogen in a single step. This will create value for industries where hydrogen is a waste product (Industrial By-Product Hydrogen) and enable separation of hydrogen and helium for natural hydrogen developers.

PILOT PLANT

PILOT PLANT

The Hydrilyte® pilot plant in Kwinana, Western Australia

From concept to reality, the Hydrilyte Pilot Plant is about to commence operation at our site in Kwinana, Western Australia. Performance Data from this project will be available to our partners by Q4 2025.

To stay up to date with the Hydrilyte Pilot Plant, please sign up to our newsletter.

Hydrilyte® Lab – Advancing Material Science

The Hydrilyte Lab is where we are pushing at the boundaries of what is possible. Our materials science and engineering research teams are constantly exploring new ways to advance the performance of Hydrilyte® and design of the Hydrilyte® systems. Our lab has achieved some major breakthroughs over the past year.

USE CASES

USE CASES

Storage & Separation

USE CASES

USE CASES

Buffering & Storage

USE CASES

USE CASES

Transport & Logistics