A breakthrough in large-scale storage of hydrogen under ambient conditions.

We are a key technology in the hydrogen supply chain, delivering what was once considered impossible: simple, safe, scalable, low-cost hydrogen storage at ambient temperature and pressure. The cost and technical complexity of storing and transporting hydrogen has been a major contributor to hydrogen projects failing to reach FID. So we created a new way.

ABOUT CARBON 280

ABOUT CARBON 280

Carbon280 is a materials science and engineering company. Our science team is encouraged to research and experiment widely and to fast-fail ideas. Our engineering team is focused on developing products that are safe for people and the environment; enable a low carbon future; and that are built for real industrial applications from day one.

OUR TECHNOLOGY

OUR TECHNOLOGY

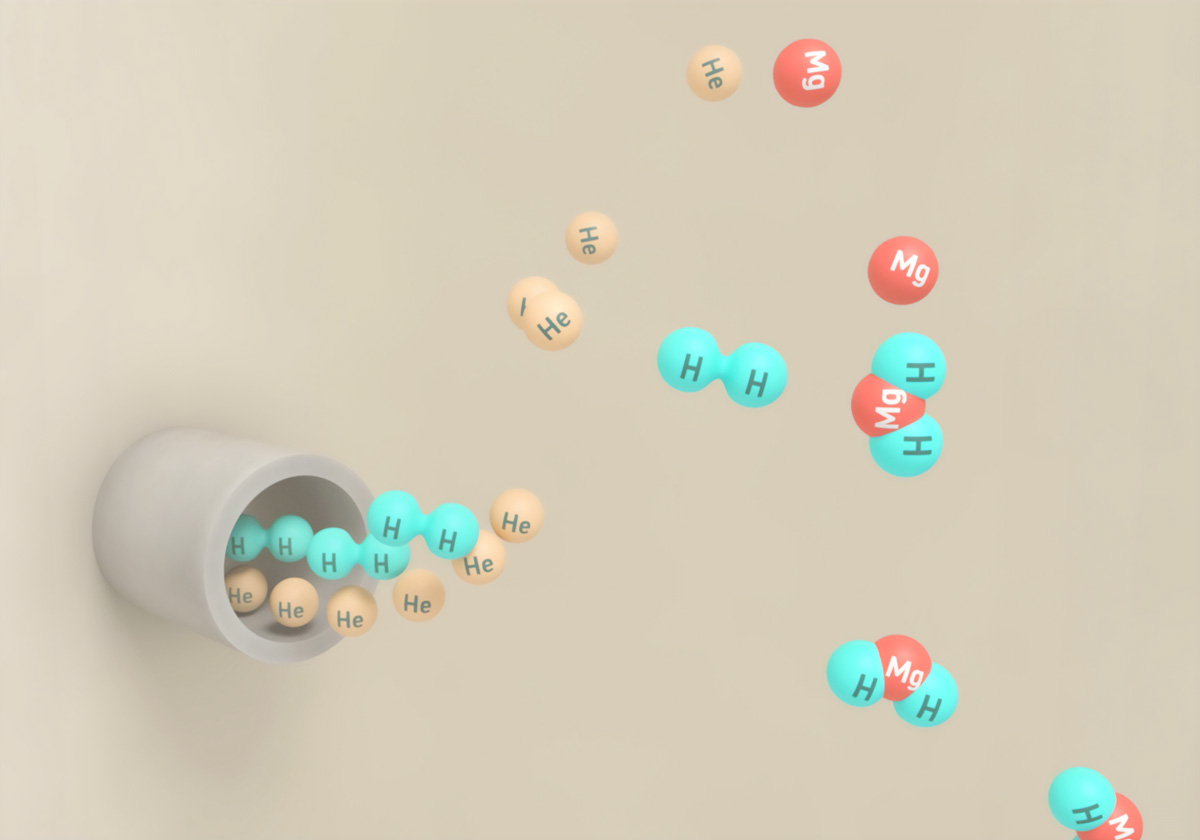

A new approach to hydrogen storage

Our starting point was that if hydrogen production is to grow five fold by 2050, as McKinsey is predicting, it must be at least as simple to handle as fossil fuels and that it should be comparatively safer for people and the environment. Hydrilyte® is so different from other approaches to hydrogen storage that it is in its own category as a liquid, metal hydride. Based on globally abundant magnesium, Hydrilyte® will not be subject to the geopolitical risks associated with rare-earth metals or indeed the platinum group catalysts that the Liquid Organic Hydrogen Carrier (LOHC) and ammonia crackers depend on.

USE CASES

USE CASES

Storage & Separation

USE CASES

USE CASES

Buffering & Storage

USE CASES

USE CASES

Transport & Logistics

LATEST NEWS

LATEST NEWS

Stay up to date with Carbon280 and Hydrilyte® through our latest news and blog updates

2025: A Milestone Year for Carbon280

It goes without saying that 2025 was a defining year for Carbon280. It marked our transition from design and development into construction, commissioning and operations of the Hydrilyte® Technology Pilot (HTP), alongside meaningful progress in...

H2EX and Carbon280 Sign a Memorandum of Understanding (MOU) at the Australian Natural Hydrogen Conference

Mark Hanna Founder and CEO of Natural hydrogen explorer H2EX and Mark Rheinlander, Founder and CEO of Hydrilyte® hydrogen purification, storage and transport producer Carbon280, today signed a Memorandum of Understanding (MOU) at the Australian Natural Hydrogen...

August Recap: Hydrilyte Pilot Plan Launch Success

In August, Carbon280 reached it’s biggest milestone to date, with the highly anticipated launch of our Hydrilyte® Technology Pilot (HTP) Plant in Kwinana, Western Australia! This state-of-the-art facility represents a significant leap forward in our mission to...